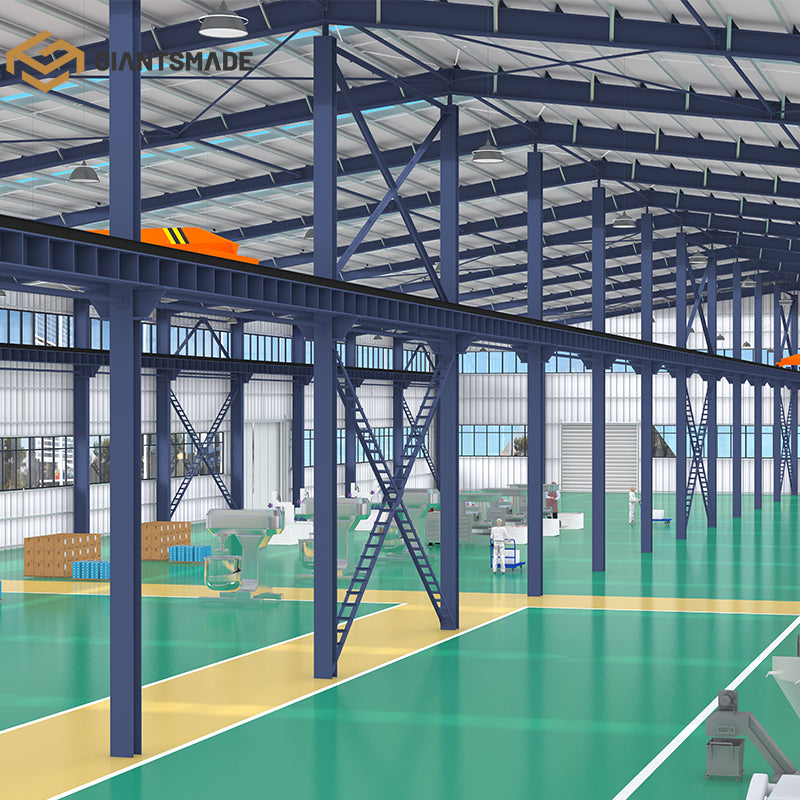

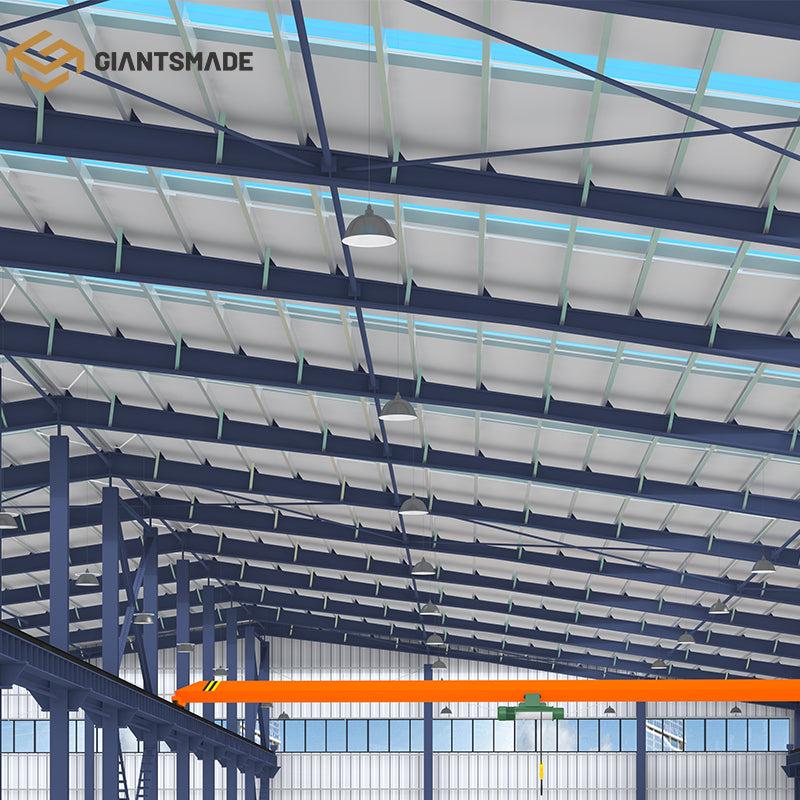

Steel Structure Workshop Prefabricated Steel Structure Storage Metal Building Kits

Steel Structure Workshop Prefabricated Steel Structure Storage Metal Building Kits

| Product Parameters | |

|---|---|

| Place of Origin: | Shenyang, China (Mainland) |

| Standard: | GB Standard, EU Standard, ASTM Standard, BS Standard, AS/NZS Standard |

| Certificates: | CE, ISO9001 |

| Grade: | Q235 / Q355 |

| Brand Name: | Giantsmade |

| Type: | Steel Structure |

| Surface Treatment: | Painted & Hot dip galvanized |

| Columns and Beams: | H-section Steel |

| Purlin: | C.Z Shape Steel Channel |

| Roof and Wall Panel: | Sandwich Panel, Color Steel Sheet |

Description

Steel structure workshop mainly refers to the main load-bearing components are composed of steel. Including steel columns, steel beams, steel structure foundations, steel roof trusses (of course, the span of the workshop is relatively large, and basically all are steel structure roof trusses now), steel roofs, and note that the walls of steel structures can also be enclosed by brick walls.

|

Specifications:

|

|

|

main steel frame

|

H section steel beam and columns, painted or galvanized, galvanized C section or steel pipe

|

|

Secondary frame

|

hot dip galvanized C purlin , steel bracing , tie bar , knee brace , edge cover etc.

|

|

Roof panel

|

EPS sandwich panel,glass fiber sandwich panel,rock wool sandwich panel,and PU sandwich panel or steel sheet

|

|

Wall panel

|

Sandwich Panel or Corrugated Steel Sheet

|

|

Tie Rod

|

Circular Steel Tube

|

|

Brace

|

Round Bar

|

|

Knee Brace

|

Angle Steel

|

|

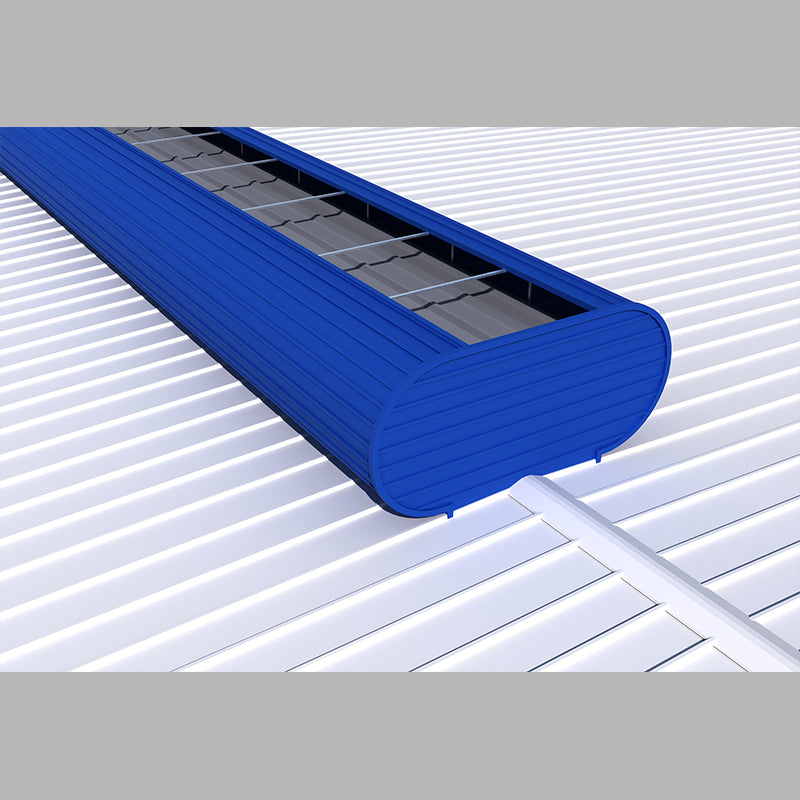

Roof Gutter

|

Color Steel Sheet

|

|

Drawings & Quotation:

|

|

|

(1) Customized design is welcomed.

|

|

|

(2) In order to give you an exactly quotation and drawings, please let us know the length, width, eave height and local weather.

We will quote for you promptly. |

|

Seismic resistance: After the color steel sheet and sandwich panel are sealed, the steel structure workshop components form a very strong “plate rib structure system”. This structural system has a stronger ability to resist earthquakes and horizontal loads, and is suitable for seismic intensity. above 8 degrees.

Wind resistance: The steel structure building is light in weight, high in strength, good in overall rigidity and strong in deformation ability, and can resist a hurricane of 70 meters per second.

Durability: The steel structure workshop is composed of cold-formed thin-walled steel component system, and the steel frame is made of super anti-corrosion high-strength cold-rolled galvanized sheet, which can effectively avoid the influence of corrosion of the steel plate during construction and use, and increase the service life of light steel components.

Durability:

The steel structure workshop is composed of cold-formed thin-walled steel component system, and the steel frame is made of super anti-corrosion high-strength cold-rolled galvanized sheet, which can effectively avoid the influence of corrosion of the steel plate during construction and use, and increase the service life of light steel components.

Thermal insulation: The thermal insulation material used is mainly rockwool sandwich panel, which has a good thermal insulation effect. The thermal resistance of R15 insulation cotton with a thickness of about 100mm can be equivalent to a brick wall with a thickness of 1m.

Comfort: The light steel wall adopts a high-efficiency energy-saving system, which has a breathing function, which can adjust the dry humidity of indoor air and ensure the ventilation and heat dissipation requirements of the roof.

Fast: Steel structure construction is not affected by environmental seasons. For a building of about 300 square meters, only 5 workers and 30 working days can complete the whole process from foundation to decoration.

Energy saving: All the walls are made of high-efficiency energy-saving walls, which have good thermal insulation, heat insulation and sound insulation effects, and can reach 50% of the energy saving standard.

Environmental protection: materials can be 100% recycled, truly green and pollution-free.

Material Structure